I'll give it a go with SD card #7, which has the AP built in and see if that is any better.

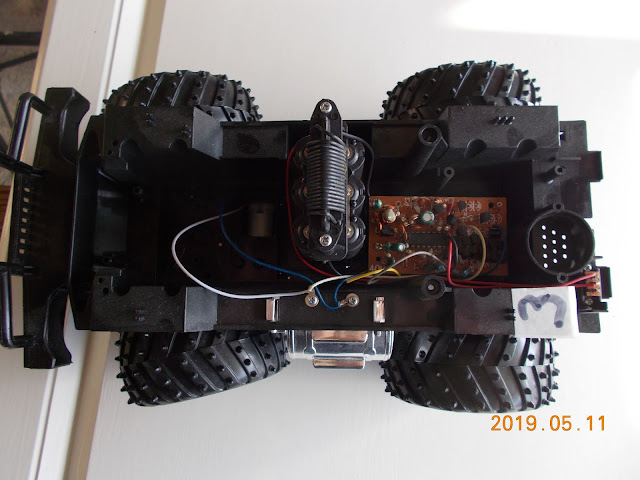

- 2019-06-13 Car number 2 with R-Pi3W and Card#7 out on the road, it works aside from the fact that left and right are wrong way around, just not very fast to respond. Is it worth doing a video showing it?

- How can I improve response times?

----------------------------

Because of the things that I have found out about pwm for driving the RC airplane servo's I might try and make the forward/back work using pwm with every press of the 'forward' button adding 5% to the pwm pulsewidth.

At the moment struggling to get basic pwm operation working in the program instead of go/stop.

---------------------------

9/9/2019

I did get this working. One of the things about PWM is that driving Remote Control Servos

uses PWM of about 1.5% to 2.5% ( these are just approx figures from my mind, check elsewhere for actual limits) To drive the car motors I noticed that it didn't do anything at 5% PWM, so I made it increase in steps of 15% and this worked fine. Another challenge was getting the feedback to display in the HTML the figure of the PWM value.

Here is the python code for the car: [some comments removed]

from flask import Flask, render_template

# This gives us control of the Raspberry Pi's pins.

import RPi.GPIO as GPIO

import time

# Tell it which pin number we'll be using to refer to the GPIO pins.

# We will use the physical pin ordering. Set initial state of pins

GPIO.setmode(GPIO.BOARD)

MotorFwd = 12

MotorBack = 16

MotorLeft = 19

MotorRight = 23

GPIO.setup(MotorFwd, GPIO.OUT)

GPIO.setup(MotorBack, GPIO.OUT)

GPIO.setup(MotorLeft, GPIO.OUT)

GPIO.setup(MotorRight, GPIO.OUT)

# PWM pin

u_d_pin_no = 18

GPIO.setup(u_d_pin_no, GPIO.OUT)

frequency_hertz = 50

pwm = GPIO.PWM(u_d_pin_no, frequency_hertz)

PWM_Stop = 0

PWM_value = 0

PWM_increment = 3

# becomes 15 after calculations

# total number of milliseconds in a a cycle. Given this, we will then

# know both how long we want to pulse in this cycle and how long tghe

# cycle itself is. That is all we need to calculate a duty cycle as

# a percentage.

ms_per_cycle = 1000 / frequency_hertz

# now lets get into Flask

app = Flask(__name__)

@app.route('/')

def index():

return render_template('index.html')

@app.route('/motor-stop/')

def on():

# motor.stop()

PWM_value = 0

duty_cycle_percentage = PWM_value

# print("Duty Cycle[S]: " + str(duty_cycle_percentage))

pwm.start(duty_cycle_percentage)

return render_template('index.html')

@app.route('/up_15/')

def up_15():

global PWM_value

PWM_value = PWM_value + PWM_increment

duty_cycle_percentage = PWM_value * 100 / ms_per_cycle

# print("Duty Cycle[F]: " + str(duty_cycle_percentage))

pwm.start(duty_cycle_percentage)

# time.sleep(.5)

# pwm.ChangeDutyCycle(0)

return render_template('index.html', PWM_PC = duty_cycle_percentage)

@app.route('/down_15/')

def down_15():

global PWM_value

if (PWM_value > 0) :

PWM_value = PWM_value - PWM_increment

duty_cycle_percentage = PWM_value * 100 / ms_per_cycle

# print("Duty Cycle[F]: " + str(duty_cycle_percentage))

pwm.start(duty_cycle_percentage)

# time.sleep(.5)

# pwm.ChangeDutyCycle(0)

# endif

return render_template('index.html')

@app.route('/motor-left/')

def motorleft():

GPIO.output(MotorLeft,GPIO.HIGH)

GPIO.output(MotorRight, GPIO.LOW)

time.sleep(1)

GPIO.output(MotorLeft, GPIO.LOW)

return render_template('index.html')

@app.route('/motor-right/')

def motorright():

GPIO.output(MotorLeft, GPIO.LOW)

GPIO.output(MotorRight, GPIO.HIGH)

time.sleep(1)

GPIO.output(MotorRight, GPIO.LOW)

return render_template('index.html')

if __name__ == '__main__':

app.run(debug=True, host='0.0.0.0')

# We have shut all our stuff down but we should do a complete

# close on all GPIO stuff. There's only one copy of real hardware.

# We need to be polite and put it back the way we found it.

pwm.stop()

GPIO.cleanup()

Having done all this I decided to do an R/C boat as it would combine the motor drive and the servo drive. I have given up on this idea because 1] I don't have a boat 2] the little motor that I was going to use didn't work with PWM and 3] I don't have a propellor.